Copyright © 2019 ZhangJiaGang JST Machinery Co.,Ltd.All rights reserved. Site Map Designed byiwonder.cn

Tel: +86-135 8442 1186

Email: admin@jstmachinery.com

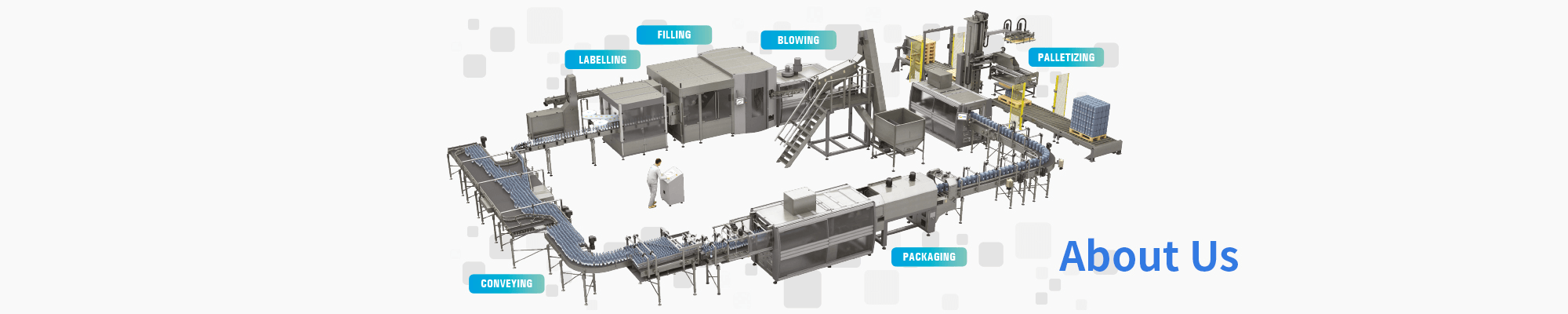

Spring is all about beautiful things and visiting a soda machine factory in this season is just an add on to it. We visited a company JST which lies in Zhangjiagang City. It is sparkling water filling machine factory. The company offers water, juices and carbonated drinks. This company also helps in designing the PET bottles, PE film size, PVC shrink labels and makes the layout as per other company requirements. We visited all departments. They have very defined lines.

It includes PET bottled carbonated drink; glass-bottled carbonated drink, and canned carbonated drink. It includes a water treatment system, bottle blowing system, filling system, labeling system, date printing system and bottle packing system with all famous electricity components, such as Siemens touch screen, PLC and so on. They can provide you PET bottle or glass bottle or tinplate can filling machine. The filling valve is isobaric pressure valves; the filling level is accurate. The capping heads adopts torque type device. The machine has an overloaded protecting device.

It includes a mixing system, pasteurization sterilizer, steam boiler, and carbonated mixing system, such as water chiller.

The water chiller is very important in the mixing system because Co2 and other liquids should be mixed at a very low temperature. Co2 and other beverages mixed in mixing machine.

They have a fully automatic type or semi-automatic type. A fully automatic type blowing machine can be connected to a filling machine directly. The common type is JST-4A and JST-6A.

The operating and machine structure is different in each type. Filling capacity will be decided after your bottle type confirmation. Afterwards they can suggest a suitable model.

You can choose to use a PVC sleeve shrink labeling machine or hot melt glue labeling machine.

There are usually two types: inkjet Date printing machine and laser type date printing machine.

There are two type of PE sytem i.e. PE film packing system and carton box packing system. Usually, the PE film shrink packing system is common, it is economic.

It includes a water treatment system, bottle blowing system, filling system, labeling system, date printing system and bottle packing system with all famous electricity components, such as Siemens touch screen, PLC and so on. They provide very good pure water by using their water treatment system, they can provide their client’s project for your reference, even you can call them to check.

It includes plastic bottles juice; glass bottled juice and canned juices. For the PET bottle, there is a juice vacuum system, juice flow back system. They can make a bottleneck spraying device and conveyor belt spraying device for you. Under the rinsing machine, there is a wastewater collecting tank with a floating ball inside to save the waste rinsing water. They have a high-quality filling line, including a mixing system, steam boiler, UHT, and the machines that after the rinsing filling capping machine.

They have an Edible oil filling machine, engine oil filling machine, detergent filling machine, corrosive liquid filling machine.

They will provide operation books and electricity drawings by email to you. They give you a 1-year warranty since delivery. They give you a proper guideline on how to install the machine they even send their engineers to install the machines. Each of their engineers is professional, they can install the complete filling line, such as water treatment system, bottle labeling machine, bottle packing machine, bottle blowing machine and bottle filling machines.