Copyright © 2019 ZhangJiaGang JST Machinery Co.,Ltd.All rights reserved. Site Map Designed byiwonder.cn

Tel: +86-135 8442 1186

Email: admin@jstmachinery.com

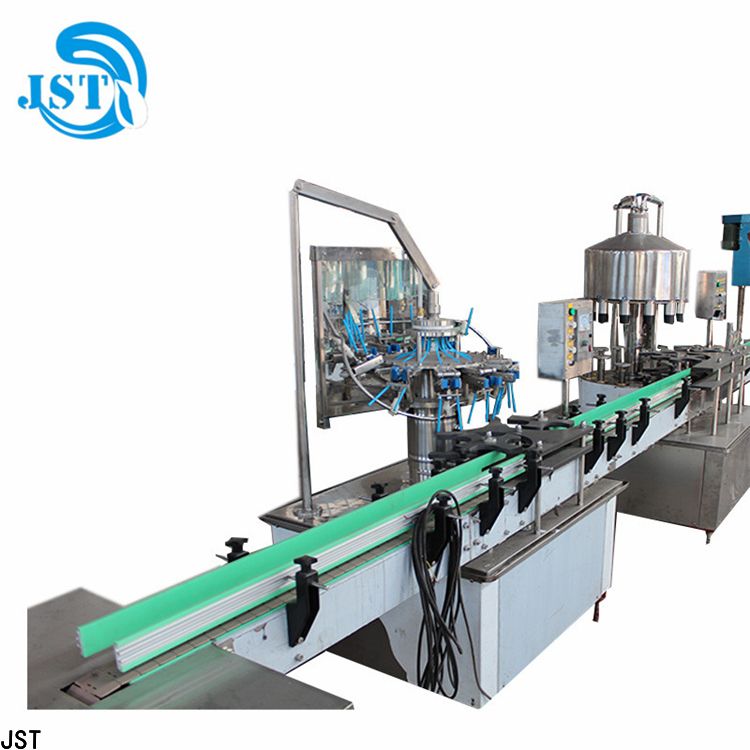

This is our glass bottle wine filling machine ,the bottle inlet ,it is sent by flat conveyor belt .We have different type ,such as 18-18-6,24-24-8, 32-32-10,40-40-12 and so on .

Rinsing heads : 18 Filling heads :18.Capping heads:6

Speed: 0-3000 bottles per hour for 500ml

Cap: long type aluminum cap or short type aluminum cap or others .

Machine size : Length :2450mm,Width : 1850mm*Height : 2200mm

Weight : 3000kgs .Working power : 5.75kw .

1. This is rinsing machine detail photo ,all the rinsing pipes ,they are stainless steel 304 type ,high quality ,not plastic type .

2. Each rinsing head ,it can be connected to the pure water ,in order to wash the inside of glass bottle .

3. Different bottle size, we just need to change the star wheel ,it is green color ,please check the above red arrow .

4.Filling machine from JST machinery with spring type mechanical lifting equipment to upgrade glass bottles, large bearing support floundering in the vat and use of guide-rod in the orientation of th e structure, there are pre-cover features.The filling station using all metal (not plastic) 304 stainless steel contact parts gives consistent accurate, high precision filling nozzle together with beverage buffer system, to ensure the high filling precision, ensure same filling level.All 304 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean.No bottle no filling.Bypass line provided for flushing the product fill tank after completion of CIP, easy clean

Item | BGF14-12-4W

| BGF18-18-6W | BGF24-24-8W | BGF32-32-10W |

Capacity(500ml) (b/h) | 2000 | 3000 | 5000 | 8000 |

Polyester bottle standard(mm) | (Bottle Diameter)50-92;(Height):150-310

| |||

Suitable cap shape | (Plastic Screw Cap) | |||

Gas consumption(m3/min) | / | 0.3 | 0.4 | 0.5 |

Total power(kw) | 3.75 | 5.75 | 7.75 | 9.75 |

Total weight(kgs) | 2500 | 3000 | 4000 | 5000 |

Size (mm) | 2200×1700×2200 | 2450×1850×2200 | 2800×2180×2200 | 3200×2800×3150 |

Machine bottom detailed photo and Siemens touch screen photo:

Before filling ,you need the water treatment system

After filling ,you need bottle labeling machine (self-adhesive label)

Usually we will pack the machines by using wrapping film first :

Then we will pack them by using standard export wooden cases :

At last ,we will load them into container :

Usually client will go to their local airport to pick our engineer up

And then engineer will assemble the machines first

At last ,engineer will test each machine

Sometimes, client will come to discuss the detail with us :