Copyright © 2019 ZhangJiaGang JST Machinery Co.,Ltd.All rights reserved. Site Map Designed byiwonder.cn

Tel: +86-135 8442 1186

Email: admin@jstmachinery.com

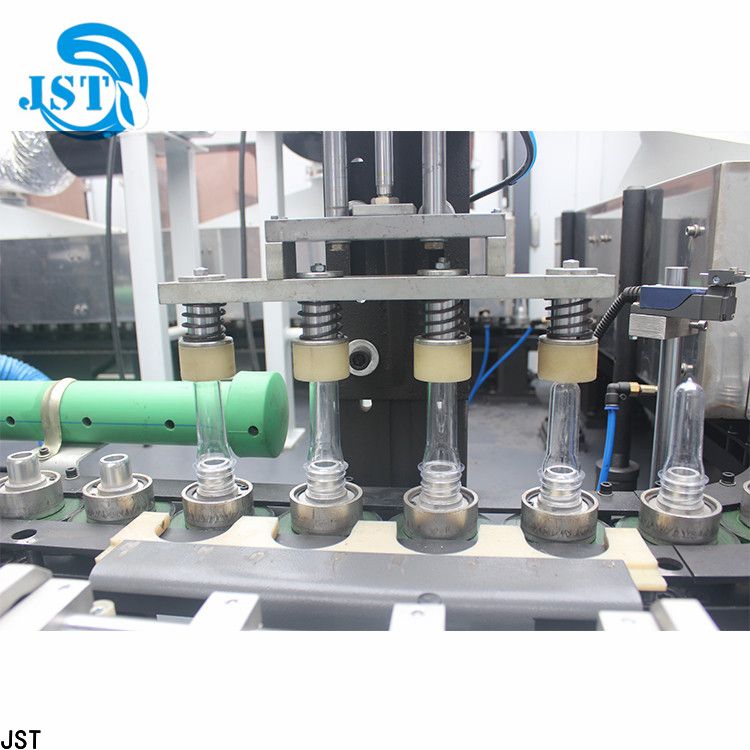

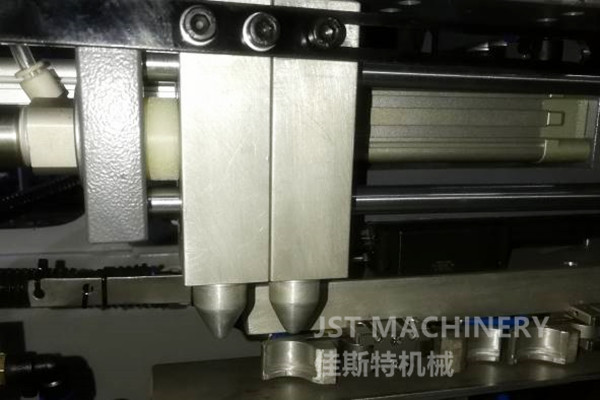

This is full automatic type ,we have 2 cavity ,3 cavity ,4 cavity and 6 cavity ,each type ,the blowing speed and machine price is also different

JST-3A reaches around 3000BPH for 500ML bottle at least .

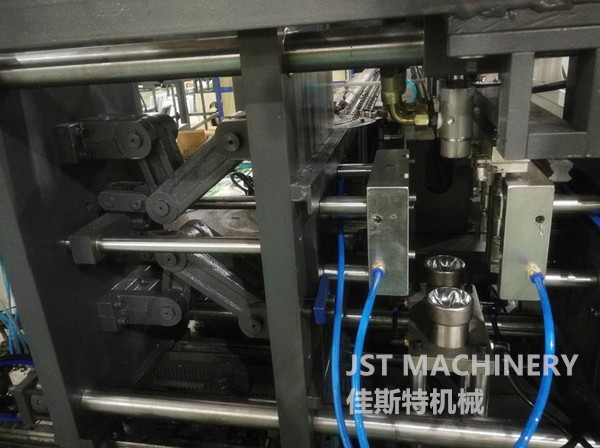

Its baking tunnel is separated from the blow station so that time for mold opening is shortened with a result of speedy blowing and high output, damage to machine is lessened so as to keep reliable performance and prolong service life, as well as machine runs more smoothly and steadily.

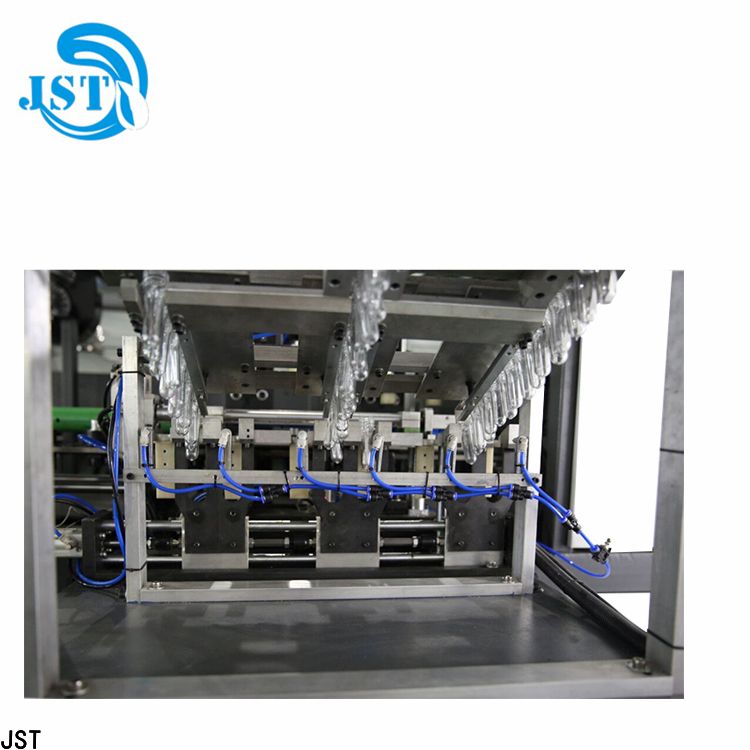

It is controlled by PLC. The whole process from preform feeding to bottle discharging is completed automatically with advantages of labor saving and no pollution. JST-6A consists of three main parts: preform loading system, Heater channel & blow station.

Machine function :

1.Machine use of advanced PLC control system , stable in performance, automatic preform feeding .

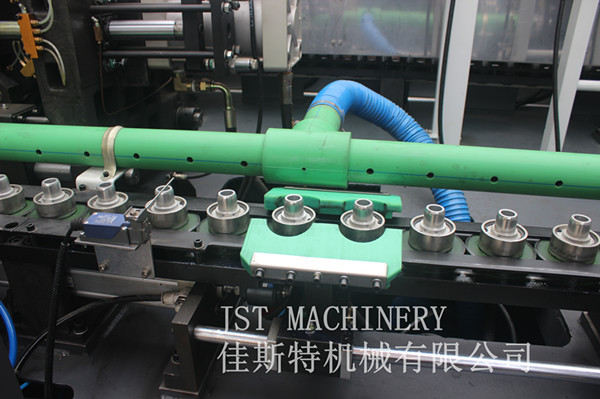

2.Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself and revolute in the rails simultaneously in the infrared pre-heater

3.High adjustability to enable the pre-heater to preheat preforms in shapes by adjusting the light tube and the length of the reflecting board in the preheating area, and eternal temperature in the pre-heater with an automatic thermostatic apparatus.

4.High safeties with security automatic-locking apparatus in each mechanical action, which will make the procedures turn into a state of safety in case of a breakdown in certain procedure.

5.No contamination and low noise with the air cylinder to drive the action instead of the oil pump

6.Air route design is divide into two parts ,

7.Ideal effect of the chilling with the chilling system

8. Low rejection rate: less than 0.3percent

Usually we will pack the machines by using wrapping film.

Then we will pack them by using standard export wooden cases .

And at last ,we will load them into container

Sometimes client will come to discuss the detail.

And sometimes, client will come to inspect and learn to train the machines before delivery :

Usualy client will go to make the customs clearance ,and take the machines to their factory

Then our engineer will go to assemble them .

And then engineer will test each machine