Copyright © 2019 ZhangJiaGang JST Machinery Co.,Ltd.All rights reserved. Site Map Designed byiwonder.cn

Tel: +86-135 8442 1186

Email: admin@jstmachinery.com

This is our two in one machine ,it is used for canned beer ,it is 12-4 filling sealing 2 in 1 ,we also have any other type ,such as 18-4,32-10 and so on.Filling speed is also different .

1.Model:18-4c(18 filling nozzles ,4 sealing heads )

Filling speed :0-8000bph @ 250ml.

Suitable can size : 150ml-1000ml.

Working power : 7.5kw

Machine weight; 4000kgs

It is used to clean empty can in canning production line. Empty cans will be sent to turning device first, which will be turned around then transferred into rinsing machine. Empty can will be running from top to bottom along the turning device. When empty cans enter into rinser, they will be cleaned by 80℃ hot water (provided by customer) to reach aseptic state of can. There is certain inclination angle in both sides of rinser, whose size could be adjusted properly when needed. Empty cans will be rolling in parallel way from top to end; the waste water will be discharged from outfall.

It is suitable for filling and capping carbonated beverage such as beer, CSD, etc. It is equipped the advanced device, electrical equipment, and pneumatic control technology. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can be equipped long-distance control system. It is the preferred equipment for the medium beer and beverage plant.

Can will be pushed into can holding platform one by one by feeding screw and star-wheel. Centering cup of filling valve will fall to can; the distance between filling valves and cans is sealed by springiness plastic ring. The movement of centering cup is generated by plastic idler wheel along curvilinear motion. After filled, valve will be closed, air is discharged, and centering cup will rise from the can. Filled can will be sent to conveyor chain, then to capper. Capper will take cap, turn over the edge of can and turn the edge to finish the sealing action by the control of cam. After that can will be transferred to conveying system.

Before filling ,you need the water treatment system and mixing tanks ,please check the following photos:

after filling ,you can chooose to use can pasteurization tunnel .

Usually we will pack the machines by using wrapping film first :

Then we will pack them by using standard export wooden cases :

At last ,we will load them into container :

First,client will go to make the customs clearance ,and take the machines to their factory ,please check the following photo:

Then usually client will go to their local airport to pick our engineer up

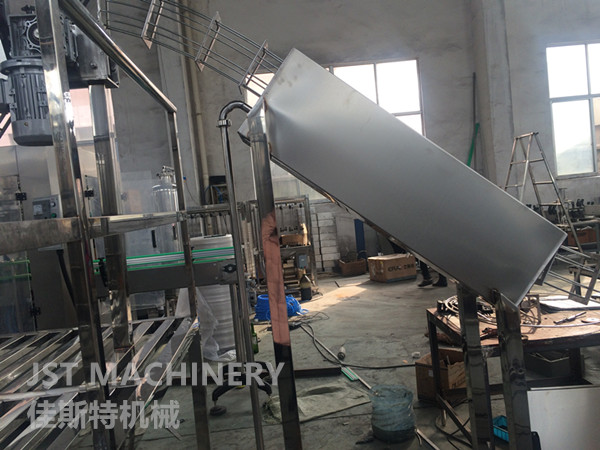

And then engineer will assemble the machines first

At last ,engineer will test each machine

Sometimes, client will come to discuss the detail with us :