Copyright © 2019 ZhangJiaGang JST Machinery Co.,Ltd.All rights reserved. Site Map Designed byiwonder.cn

Tel: +86-135 8442 1186

Email: admin@jstmachinery.com

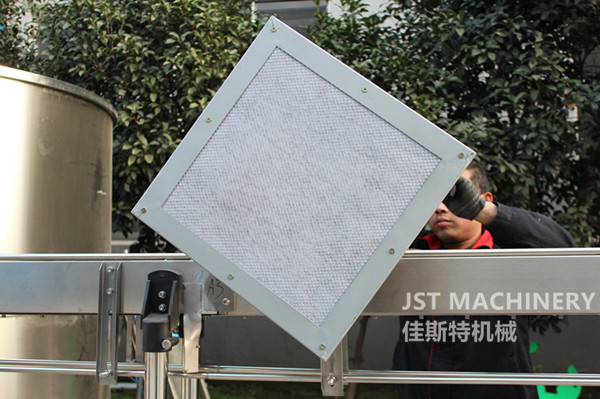

The full-automatic bottle sorting machine is mainly suitable for the matching use of large-scale high-speed production equipment. It has the properties of automatic feeding, automatic bottle sorting, bottle discharging arrangement and so on. It is an indispensable equipment in high-speed production line

The disordered bottles are poured into the lifting hopper of the bottle sorting machine and transported into the cylinder of the bottle sorting machine by the elevator belt. The bottle guide rod drives the bottles to enter the lower bottle box along the track. The bottles are turned down in the lower bottle box, and then transferred into the air supply chain channel by the star wheel. The air supply chain channel is connected with the filling machine and enters the three in one unit of washing, filling and capping. The whole working process is automatically controlled by PLC.

LP-16

Large production capacity: 0-12000 bottles / hour

Applicable bottle shape: diameter 50-90, bottle height 165-290

Main motor power: 7.5kw

Boundary dimension: Φ 2100 * 2140

Operating weight: 1500kg

We also have LP-14,LP-18,LP-20 type ,the production capacity is different .

The main motor reducer adopts a torque limiting mechanism to prevent damage to the machine in case of failure.

Two times of pushing and bottle discharging mechanism is adopted to ensure that there are bottles in each bottle dropping station, so as to improve the efficiency of bottle discharging.

The air duct with bottle mouth is adopted to avoid bottle overturning during conveying.

A broken bottle removal mechanism is provided.

It is equipped with bottle clamping detector, which can automatically stop the machine and give an alarm when the bottle is clamped.

A bottle free detector is set to send a working signal to the elevator, which will automatically replenish bottles.

A photoelectric switch is installed on the bottle conveying air duct to control the start and stop of the bottle handling machine.

The bottle handling machine is equipped with an oil filling nozzle, which can easily add lubricating oil to gears, bearings and cams.

Equipped with maintenance door and mold replacement door.

Main electrical components (frequency converter, PLC, photoelectric switch, relay) are Mitsubishi, Omron, Siemens and other components

Sometimes client will come to discuss the detail.

And sometimes, client will come to inspect and learn to train the machines before delivery :

Usualy client will go to make the customs clearance ,and take the machines to their factory

Then our engineer will go to assemble them .

And then engineer will test each machine