Copyright © 2019 ZhangJiaGang JST Machinery Co.,Ltd.All rights reserved. Site Map Designed byiwonder.cn

Tel: +86-135 8442 1186

Email: admin@jstmachinery.com

This is linear type for detergent filling line ,there are 6 filling heads machine ,8 filling nozzles ,10 filling nozzles ,12 filling nozzles and so on . It can be used for round bottle ,square bottle ,or irregular shapped bottle .

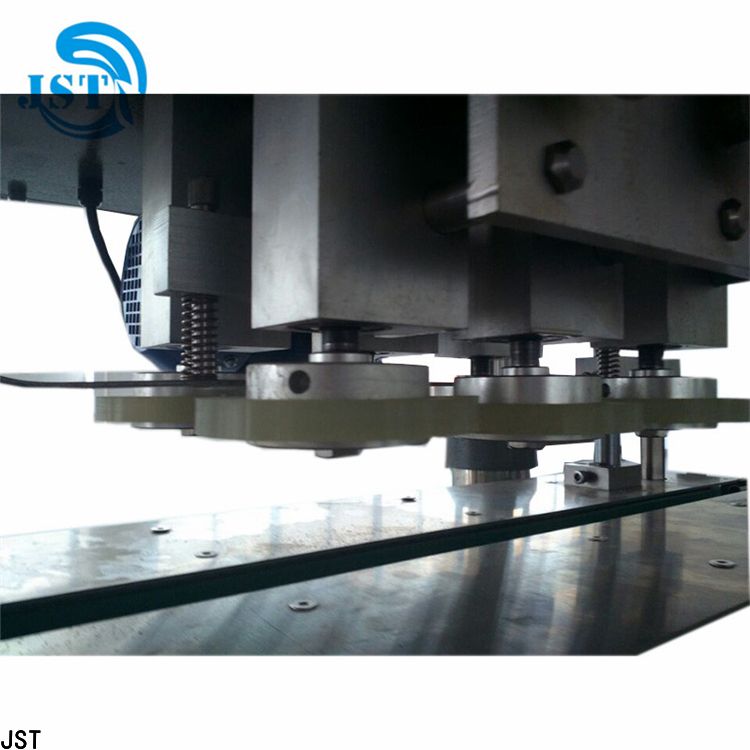

1.Suitable material:Bleach,acid liquid,84 disinfectant,gel water,toilet cleaner,eapecially used in the liquid filling of stromgly corrosion liquid and cosmetics which can’t touch the metal.This machine is our special design and enjoy good reputation in world market . All the contacted part with the filling material,we will make into PP. The machine adopts piston pump for filling. By adjusting the position pump, it can fill all of the bottles in one filling machine, with quick speed and high precision.

2.Contact liquid parts are use anticorrosive non-metallic material and with diving function.

3.This Vertical filler is a high-tech filling equipment integrating on the PLC microcomputer programmable control, and photo electricity transduction pneumatic action.

4.The machine suits for the filling of different sizes of vessel may change the filling sizes within a few minutes. Short filling circle, high production capacity.

Speed: 0-3500 bottles per hour (for 1000ml/ 12heads)

Measurement precision ±1%

Bottle sizes : 1000-5000ml,special bottle need to be made according to order .;Working air pressure 6-7kg/m²

Net weight : 3000kg ;Machine : 3500×1200×2100mm

About the PLC+Touch screem ,:Siemens brand

It has servo driver together .

First ,we will pack the machines with shrink wrapping film

Then we will pack all the machines in standard export wooden cases

And at last ,we will load all the machines into container .

After delivery ,client needs to make customs clearance by himself .

And take the goods to his factory .

Then our engineer will go to assemble all the machines

And then our engineer will test each machine for him .

Sometimes, client will come to discuss the detail with us .

Sometimes, before delivery ,client will come to inspect each machine