Copyright © 2019 ZhangJiaGang JST Machinery Co.,Ltd.All rights reserved. Site Map Designed byiwonder.cn

Tel: +86-135 8442 1186

Email: admin@jstmachinery.com

This machine ,it is suitable for 3 gallon or 5 gallon , it is 3 in 1 machine . made up of rinsing ,filling capping together .We also have any other auxiliary machine,such as cap removing machine ,bottle leakage checking machine ,inside and outside brushing machine ,light checker ,bottle neck shrinking machine and so on . We also have many different types ,such as QGF-120, QGF-300,QGF-450,QGF-600 ,QGF-800 ,QGF-1000 and so on .

QGF-600 is an automatic barrel production line for drinking water of 3-5gallon. Meanwhile, it is also suitable to produce barrel wine, vinegar, medicine and so on. This production line is adopted sufficiently tech-knowledge from overseas’ drinking water equipment and plus our elaborately design due to our nation tradition to work out. So it has full functions, low energy consumption, low investment, and higher and fast effecting characteristic.This machine has advantage on new design, concise structure, higher precise filling, widely use, , and higher robotization. It is new model drinking water production line.

For 5 gallon, filling speed : 600bottles per hour .

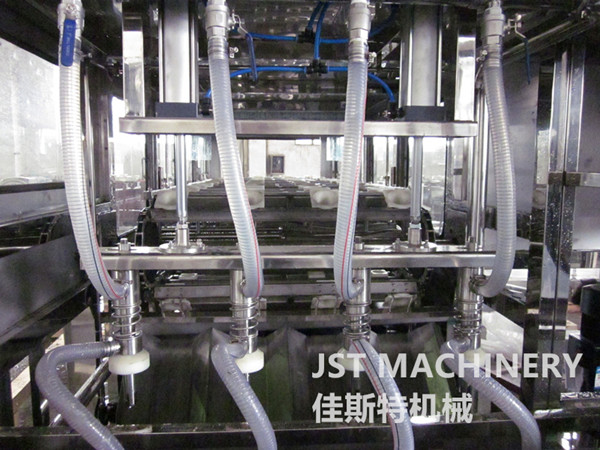

Filling filling :there are 4nozzles

And the capping ,it is snapped type .

Usaully for cap ,we will match one cap sterilizer for you (It uses Ozone and UV to kill the bacterium )

Model: QGF-600

Filling Heads:4

Filling Volume: 5 Gallon

Size of Barrel: ф276×490mm

Capacity:600 barrels per hour

Power supply: depends on buyer request.

Max power consumption 5.5 kw+ heating 9 kw the Power consumption is only 5.5kw while the machine works as each electrical part starts intermittently

Volume of using water: Filling11.5T/H; Purified water washing 3 T/H

Rinsing detailed photo :

Filling detailed photo:

Capping detailed photo:

Usually we will pack the machines by wrapping film in advance.

Then we will pack the machines by export standard wooden cases .

If machines is too big, we will not pack them with wooden cases .We will fix it to the container directly.

An at last ,we will load the machines into the container.

Usually ,client will go to pick our engineer up at their local airport.

And then engineer will go to their factory to connect each machines by sending conveyor belt

And then, engineer will test each machine

Sometimes ,client will come to our factory to check the detail beforo placing the order

Cap removing machine :

Bottle Outside brushing machine :

Bottle inside brushing machine :