Tel: +86-135 8442 1186

Email: admin@jstmachinery.com

Tel: +86-135 8442 1186

Email: admin@jstmachinery.com

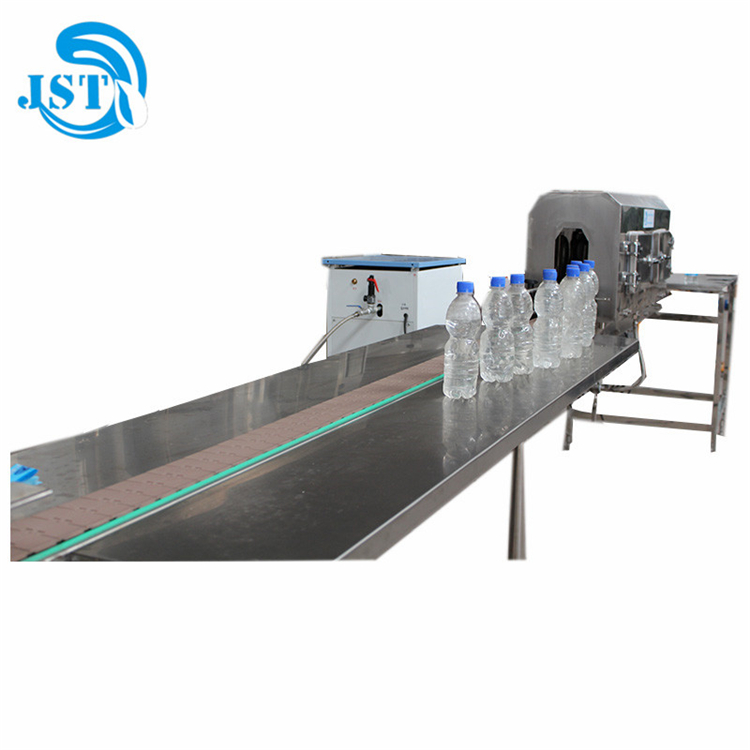

This is linear type juice filling line ,it is fit for small filling speed ,for 500ml ,maximum filling speed will be 1500 bottles per hour .You can change the filling speed by operating panel. There is also auxiliary machines, such as mixing machine ,labeling machine ,bottle packing machine and bottle strength blowing machine .

There will be 12 heads. It has door cover to protect the workers from being hurt when its running .

Machine size :1050mm*950mm*1800mm

Weight :500kgs

Power :1.75kw

Rinsing water : 200liter / hour

There will be 12 heads .It has door cover to protect the workers from being hurt when its running .

Machine size :1050mm*950mm*1800mm

Weight :550kgs

Power :1.75kw

Filling speed : 0-1500 bottles per hour @ 500ml

There will be 1 head .It has door cover to protect the workers from being hurt when its running .

Machine size :950mm*900mm*1800mm

Weight :450kgs

Power :1.75kw

For linear type, usually the labeling machine ,it will be semi-automatic PVC sleeving type ,and the packing machine, usually semi-automatic PE film shrink packing machine is common.

And for bottle blowing machine ,usually semi-automatic PET blowing system is common .

We have linear type filling line in Suriname ,Bhutan, Bolivia, Zimbabwe, and so on .

the following photos is our client's product photos after the linear type water filling line .

If you need more information ,please feel free to contact us by email or whats app or call.

Raw water storage tank→ Raw water pump→Quartz sand filter →active carbon filter →sodium ion exchanger →precision filter →reverse osmosis →UV sterilizer →Ozone generator →pure water storage tank.

Semi-automatic Packing machine :

Semi-Automatic Blowing machine :

One PVC labeling table +One shrink oven +One steam generator

Juice mixing system photos :

These are Zimbabwe clients for linear type water filling line :

The following photo is for our Bhutan clients ,his is linear type water filling line ,he goes to pick up our engineer

And our Engineer install the filling line for him :

We will pack all the machines with wrapping film first ,then we will pack all the machines with standard export wooden boxes .

And then all the machines will be loaded to the containers .