Copyright © 2019 ZhangJiaGang JST Machinery Co.,Ltd.All rights reserved. Site Map Designed byiwonder.cn

Tel: +86-135 8442 1186

Email: admin@jstmachinery.com

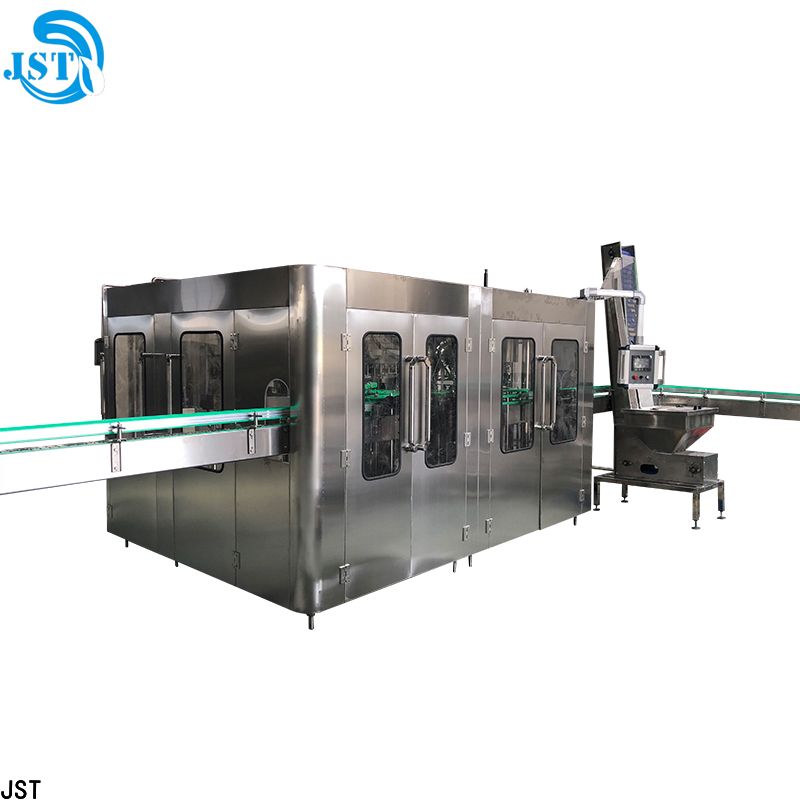

This machine ,it is fit for PET bottle, bottle size can be from 250ml t0 2000ml. We have differen model, such as RCGF 8-8-3 ,16-12-6,18-18-6,24-24-8,32-32-10 ,40-40-12,50-50-15 and so on . Different type ,filling speed is also different ,Machine price is also different . Before you place the order ,please tell me ,will you need the juice to be filled in room temperature or hot filling temperature ? Because the mixing system and jucie machine and blowing machine will be different .

1.Model:RCGF 18-18-6

Filling speed :0-4000bph @ 500ml.

Suitable bottle size : 200ml-2000ml.

This filling machine ,it is used to fill pulp juice ,and inside the filling tank ,there is blender together.

Usually for filling tank ,filling nozzles, we will make them into SS316L.

The Juice beverage filling machine is mainly used for hot filling machine and sealing of green tea, black tea, and fruit juice drink.It can be used to fill pure water or mineral water or still water ,just need to lean the juice filling macine nozzle and pipes.

Adopt PLC as center controller, make use of pressure transmitter and electromagnetism pneumatic valve to measure liquid level, and keep balance of filling pressure to insure stable liquid level.

Adopt new type filling valves from jst mchinery which are especially designed for plastic bottles. The returned air and the liquid in filling tank are insulated to insure cleanliness of the filled beverages.4. Adopt advanced magnet clutches for capping with adjustable tensional moment to insure capping safely and reliably.

Item | RCGF16-12-6

| RCGF18-18-6 | RCGF24-24-8 | RCGF32-32-10 |

Capacity(500ml) (b/h) | 3000 | 5000 | 10000 | 14000 |

Polyester bottle standard(mm) | (Bottle Diameter)50-92;(Height):150-310

| |||

Suitable cap shape | (Plastic Screw Cap) | |||

Gas consumption(m3/min) | / | 0.3 | 0.4 | 0.5 |

Total power(kw) | 3.75 | 5.75 | 7.75 | 9.75 |

Total weight(kgs) | 2500 | 3000 | 4000 | 5000 |

Size (mm) | 2200×1700×2200 | 2450×1850×2200 | 2800×2180×2200 | 3200×2800×3150 |

1.Different bottle size ,we will make exchanged spare parts for you .Please check the following green sparep arts photo:

2.For plastic bottle juice filling line ,will you need to fill juice in room temperature or hot filling temperature ?

The mixing system ,and the machines after filling machine will be different ,please check the following photo:

Complete filling line photos for juice hot filling :

Machine bottom detailed photo and Siemens touch screen photo:

Before filling ,you need the water treatment system and jucie mixing system ,please check the following photos:

If you need hot filling ,after filling ,you still need bottle tumbling conveyor belt ,bottle cooling tunnel.

Bottle cooling tunnel photo:

Usually we will pack the machines by using wrapping film first :

Then we will pack them by using standard export wooden cases :

At last ,we will load them into container :

Usually client will go to their local airport to pick our engineer up

And then engineer will assemble the machines first

At last ,engineer will test each machine

Sometimes, client will come to discuss the detail with us :